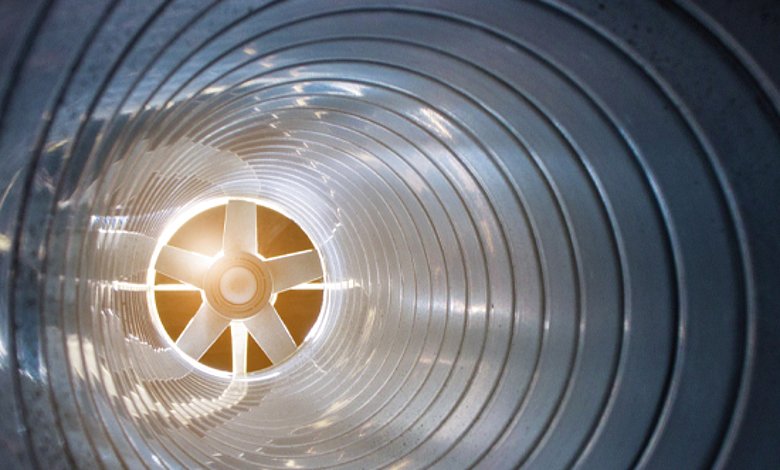

In a mature dandelion flower, the smallest pressure differences are enough to send its umbrellas on a kilometer-long journey. For a human being, this breeze is hardly noticeable - but it is for our differential pressure measurement technology. Differential pressure measurement determines the pressure difference between two pressure potentials. The measurement technology is mostly used in ventilation systems, clean rooms or on filter systems. For example, volume flow can be measured, the overpressure of a system or the degree of filter contamination can be precisely determined.

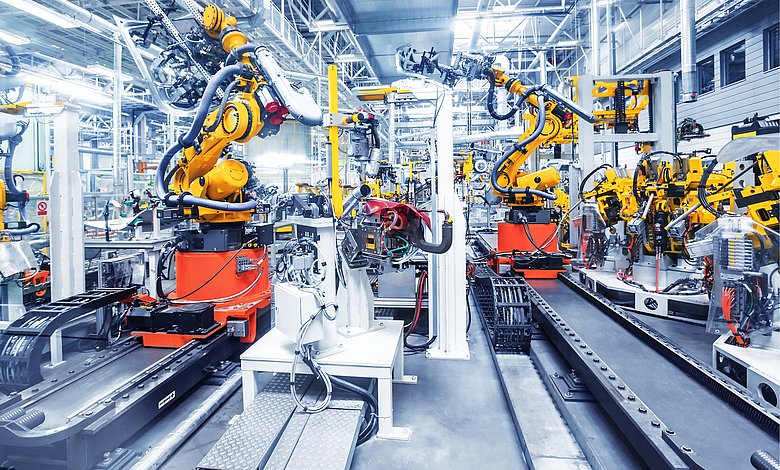

The detection of differential pressures in the low-pressure range is used wherever the precise determination of the smallest pressure differences has a significant influence on process reliability. In industry, for example, differential pressures are measured to monitor filters or to measure filling levels. In the field of building automation, differential pressure measurement technology is used to determine and control the volume flow in a ventilation duct. In clean rooms or operating rooms, the measuring systems are used to control and monitor the minimum overpressures that protect critical areas from contamination with dirt particles.

To measure differential pressures, two system pressures are measured and the difference between their values is determined. A differential pressure transmitter therefore consists of a system with two pressure connections, a measuring element and measuring electronics. The measuring element is usually a piezoresistive differential pressure sensor with a silicon-based measuring diaphragm. As the differential pressure changes, the measuring diaphragm expands in one direction or the other, thus changing its electrical properties. This change is passed on via an interface to the measuring electronics, which process the signal further and convert it into a standardized analog or digital output signal.